The Hudson Company

Wood in All its Glory

We walk on wood floors, we store our possessions in wooden drawers, we slam wooden doors. In many ways we take wood for granted. But Jamie Hammel, founder and president of the Hudson Company in Pine Plains NY loves wood and has mastered the art of reclaiming and restoring old wood.

Walking through the main warehouse one encounters mountains of wood, salvaged, preserved and repurposed—a boon to the environment and for those who appreciate history.

In 2010 Hammel purchased an existing company called Antique and Vintage Woods of America, on the site that now houses Hammel’s company. At the time, the reclaimed wood industry was not given much respect. Materials were often harvested using unscrupulous practices and there was no guarantee that a floor would be delivered as ordered. But Hammel has changed that impression, taking advantage of the antique lumber marketplace’s growing hunger for handmade products by developing a high standard of quality with guarantees and warranties. Still, the process has not been without challenges.

“I like design,” says Hammel, “and the floor is the canvas on which you build everything. I bought someone else’s inventory and there were piles of varying heights everywhere – dusty, dirty wood. But I knew this was a treasure trove of product.”

Hammel’s previous career offered no clue that he would wind up running a lumber mill. It had nothing to do with wood or history.

“I was leaving a corporate career in the media industry,” Hammel explains. “and I had also been involved in the dot.com and venture capital worlds. I had great experience in building businesses that I couldn’t touch. I wanted to build one that I could touch. So, I made a 180-degree turn and found something very tangible in the world of wood.

“I have an entrepreneurial spirit and I was determined to make it work and I learned the hard way,” he continued. “I spent many nights in the cold, dark Hudson Valley, in the middle of winter, wondering what I was going to do. It took a great deal of persistence and teamwork. I hired people who knew a lot more about wood and machinery than I did.”

To find product that met his standards, Hammel drove all over the country, looking at barns and other structures about to be torn down. Often, he got the wood for free from demolition crews. Now that reclaimed wood with a history has become trendy, Hammel works with demolition contractors to find his product. And it can come from various sources, both near and far: materials from the renovation of the Park Avenue Armory, a mushroom farm in Pennsylvania, a dairy farm in Maryland, from the elevated railway in Manhattan’s meatpacking district. All have played a part in Hammel’s goal to preserve both the wood and the history.

“People like the stories behind the product,” Hammel says. “Reclaimed wood tells a tale. The patina, some of the imperfections like nail holes, ferrous stains, the history of the original structure and of what was happening in the country at that time. Some of the timber we use was cut the day after the Civil War ended. The length, the color. It all contributes to its appeal.”

“Even if the history is not significant, there is still a pleasure in preserving something original. We took the old threshing floor from a barn. Animals had walked over it, tractors were parked on it. The flooring was two inches thick. We remilled it to about an inch and a quarter and now it can be used in a modern structure.”

Once the original product from the demo site comes into the mill, the restoration process begins. First it gets denailed; then it’s put into a kiln where all the moisture is extracted. The wood is then cut into the size required for its repurposing.

While the Hudson Company operates a street-level showroom in New York City, it tends to market its products through the trade. An architect or designer will specify the floor be milled through the Hammel’s facility. Last year the company also opened a showroom in Ridgefield CT.

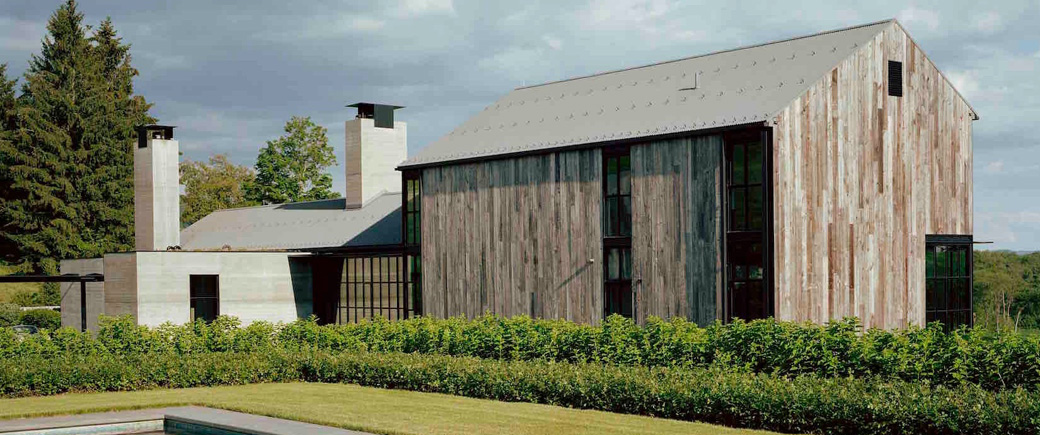

Over the years there have been countless projects that illustrate the quality of the products and expertise of The Hudson Company, including Sunny Fields, a horse farm and Georgian-style home in Millbrook NY; 1 Hotel Central Park, part of the Starwood Hotel chain; the historic buildings at 60 White Street in Tribeca where more than 18,000 square feet of reclaimed oak was used for both flooring and paneling. But the award for the most impressive project goes to the Whitney Museum of Modern Art in downtown Manhattan.

Here the Renzo Piano Workshop specified that Reclaimed Heart Pine be used for the flooring in the new building. The Hudson Company custom-milled more than 275,000 board feet of reclaimed timbers to craft the 65,000-square-feet of flooring for the museum’s needs, creating the largest reclaimed floor in the country.

Toby Stewart, an architect with the Renzo Piano Building Workshop, felt the reclaimed pine was the clear choice for the flooring as it’s hard enough to withstand foot traffic yet soft enough to allow the workability the museum required.

As expected these boards had their own unique history. The Heart Pine planks that would become the Whitney’s new flooring came from antique timbers from abandoned industrial sites, including a Philip Morris factory in Louisville, KY and a Maidenform Factory in Bayonne NJ.

The Hudson Company is unique in that it custom manufactures its products and also has its own showrooms, sales and marketing resources which explains why customers are pleased to do work with Hammel and his staff.

“I feel lucky in having dedicated people at every level,” says Hammel. “I really love what I do. A few days a week I am on a construction site looking at this beautiful raw material. On the same day, I can be in an architect’s office talking about a new project. It makes my job totally rich.”

For further information please click on the link below.